1.5″ Flange Out

1.5″ turned out with open corners on the end designated, often used for drops and ceiling boxes.

1″ DW EZ-Flange Installed

SMC will factory install your E-Z flanges with the inner flange extended to nose off the insulation on both ends of your parts. This also holds the inner pipe or fitting perfectly centered to maintain the integrity and R-value of your liner.

SPECS1″ Flange In

1″ turned in on the end designated.

1″ Flange Out

1″ turned out with open corners on the end designated, often used for drops and ceiling boxes.

1/2″ Conduit DBL Wall

1/2″ Diameter electric metallic tube with galvanized zinc coating is cut to length with star nuts are installed into each end and installed into your duct to provide added rigidity and strength against deflection. In Doublewall duct conduit will pass through the inner and attach to the outer pressure shell.

SPECS1/2″ Conduit Installed

1/2″ Diameter electric metallic tube with galvanized zinc coating is cut to length with star nuts are installed into each end and installed into your duct to provide added rigidity and strength against deflection.

SPECS1/2″ Conduit KD

1/2″ Diameter electric metallic tube with galvanized zinc coating is cut to length with star nuts are installed into each end and shipped loose for you to install into your duct in the field to provide added rigidity and strength against deflection.

SPECS1/2″ Flange In

1/2″ turned in on the end designated.

2″ DW EZ-Flange Installed

SMC will factory install your E-Z flanges with the inner flange extended to nose off the insulation on both ends of your parts. This also holds the inner pipe or fitting perfectly centered to maintain the integrity and R-value of your liner.

SPECS2″ Flange Out

2″ turned out with open corners on the end designated, often used for drops and ceiling boxes.

3-Way Tap In

3″ DW EZ-Flange Installed

SMC will factory install your E-Z flanges with the inner flange attached to the outer flange with nosing pieces via tack weld to nose off the insulation on both ends of your parts. This also holds the inner pipe or fitting perfectly centered to maintain the integrity and R-value of your liner.

SPECS3/4″ Conduit DBL Wall

3/4″ Diameter electric metallic tube with galvanized zinc coating is cut to length with star nuts are installed into each end and installed into your duct to provide added rigidity and strength against deflection. In Doublewall duct conduit will pass through the inner and attach to the outer pressure shell.

SPECS3/4″ Conduit Installed

3/4″ Diameter electric metallic tube with galvanized zinc coating is cut to length with star nuts are installed into each end and installed into your duct to provide added rigidity and strength against deflection.

SPECS3/4″ Conduit KD

3/4″ Diameter electric metallic tube with galvanized zinc coating is cut to length with star nuts are installed into each end and shipped loose for you to install into your duct in the field to provide added rigidity and strength against deflection.

SPECSB.I Ring Tack Weld

Black iron companion ring installed on the end of pipe or fitting and held in place with 1″ tack welds every 6″ around the piece.

SPECSB.I. Ring Full Weld

Black iron companion ring installed on the end of pipe or fittings and held in place with continuous full welde around the entire circumference of the piece.

SPECSB.I. Ring Swedged Fitting

Black iron companion ring installed loose on round fittings with the end then swedged out to hold the ring on.

SPECSB.I. Ring Swedged Pipe

Black iron companion ring installed loose on spiral pipe with the pipe then swedged out to hold the ring on.

SPECSButyl Gasket

Butyl gasket is a one component non-drying permenantly flexible material designed for sealing rigid joints between ductwork.

SPECSCoil Injected

Sealant spottily applied by the automatic sealer on the standard length duct coil line pieces. No cost is added as the sealant is not guaranteed to have adequate coverage to seal duct thoroughly.

SPECSComplete Seal

Complete Seal fittings are manufactured from galvanized steel. They feature a double legged EPDM gasket which creates a virtually airtight connection when slipped into spiral pipe. The gasket is mechanically attached to the fitting with a 180 degree hemmed edge. This hem gives added rigidity to the fittings, ensures that the gasket will never slip out of place and makes a safe rounded edge for the installer.

SPECSDrip Edge

1/2″ of material turned out at 45 degrees at the bottom of a fitting to direct water away from the base. Generally used on curb adapters and curb covers.

Drive & Slip

Flipped slip and drive construction, drives will default to the width of the part enterd and slips will default on the height.

Duct – Pittsburgh Assembled

Pittsburgh seam for coil line duct assembled in the factory.

Duct – Snaplock Assembled

Snaplock seam for coil line duct assembled in the factory.

Duct Painted Sealer

Sealant is applied after the standard length coil line duct pieces are assembled. Sealant may be applied by caulk gun, brush, or spray.

SPECSE-Z Flange Disc

E-Z flange disc is strictly for use with E-Z flange end caps. SMC will fabricate a flat disc that will mate to the outside of your opposite E-Z flange that does not require an additional E-Z flange installation, saving you money and providing a clean look at installation.

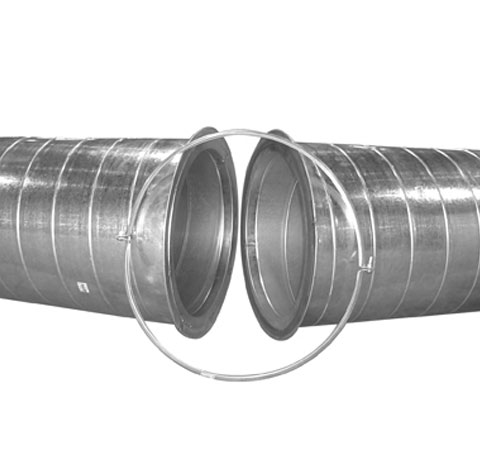

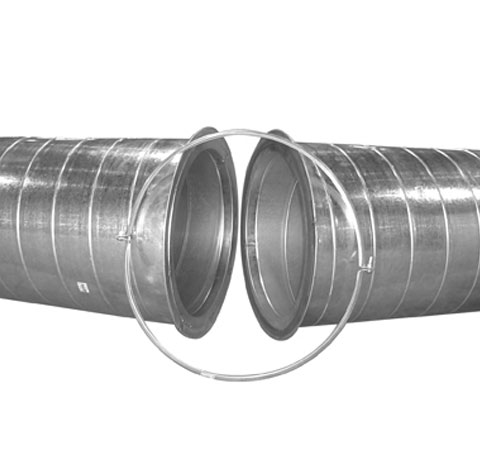

E-Z Flange Installed

SMC will factory install your E-Z flanges for both Jr. Flange (6″-24″) and Sr. Flange (26″ + up). Jr. flanges are formed directly on to your pipe and fittings while Sr. flange is slipped in, tack welded in place, and sealed.

SPECSFitting Painted Sealer

Sealant is applied after all fitting pieces are assembled and accessories are installed. Sealant may be applied by caulk gun, brush, or spray.

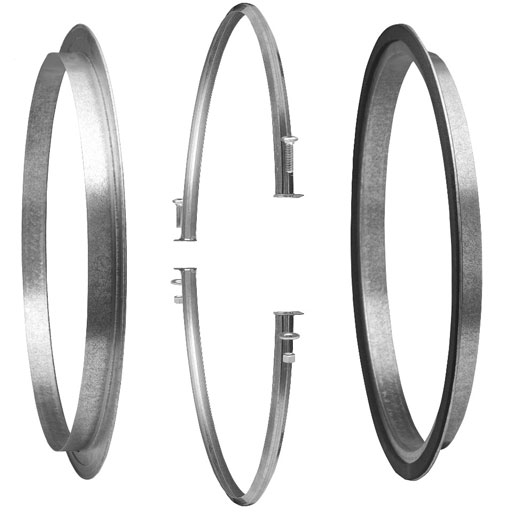

SPECSGalv Ring Full Weld

Galvanized companion ring installed on the end of pipe or fittings and held in place with continuous full welde around the entire circumference of the piece.

SPECSGalv Ring Swedged Fitting

Galvanized companion ring installed loose on round fittings with the end then swedged out to hold the ring on.

SPECSGalv Ring Swedged Pipe

Galvanized companion ring installed loose on spiral pipe with the pipe then swedged out to hold the ring on.

SPECSGalv Ring Tack Weld

Galvanized companion ring installed on the end of pipe or fitting and held in place with 1″ tack welds every 6″ around the piece.

SPECSInside Tap

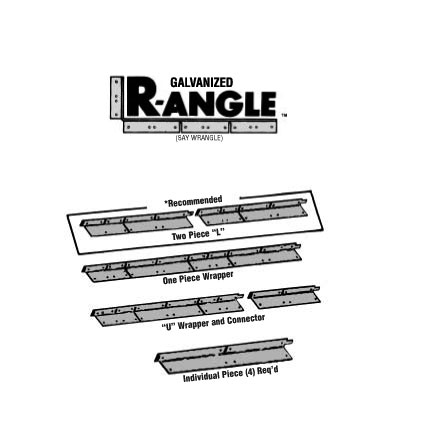

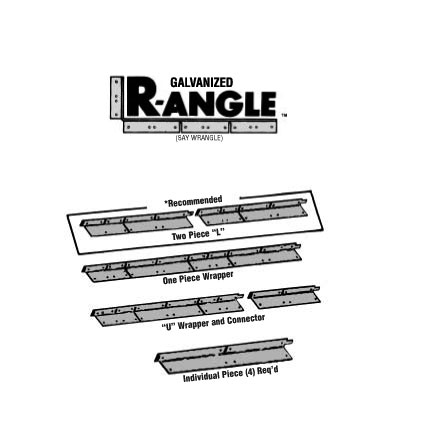

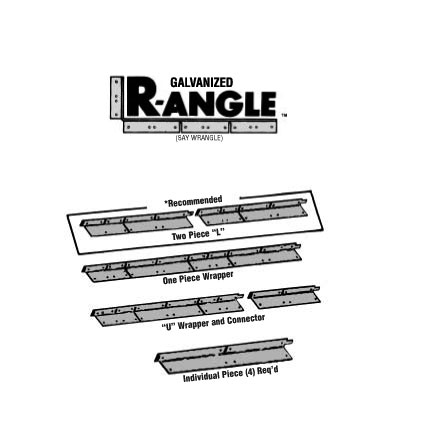

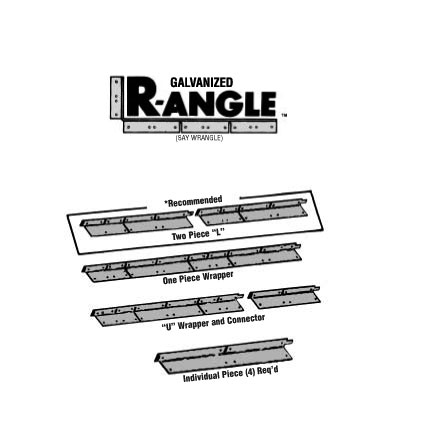

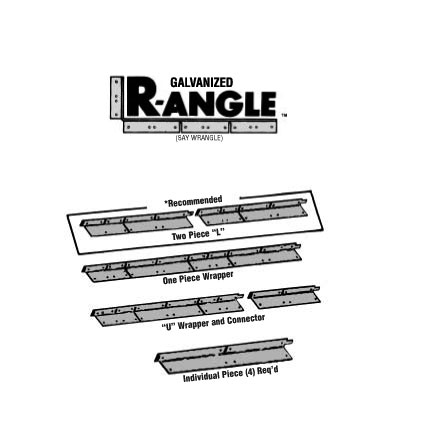

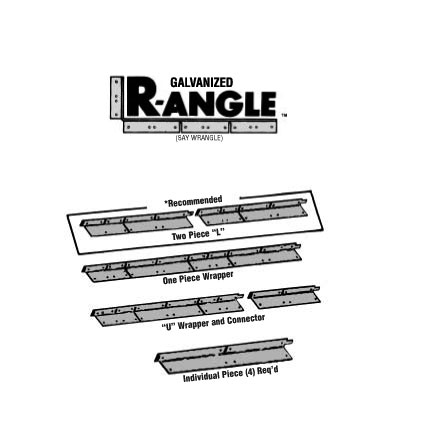

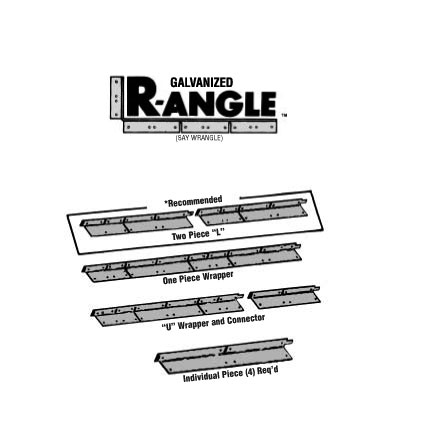

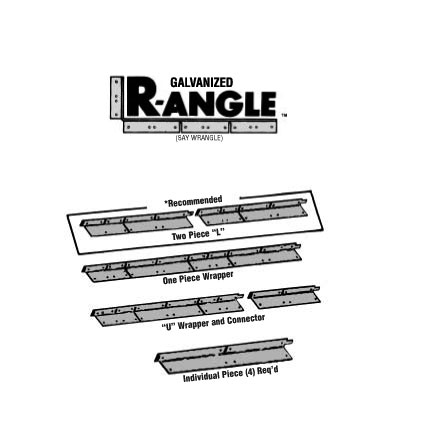

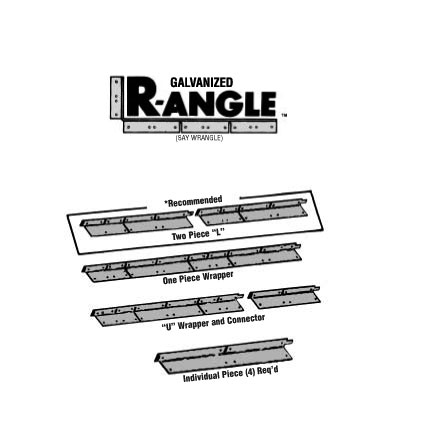

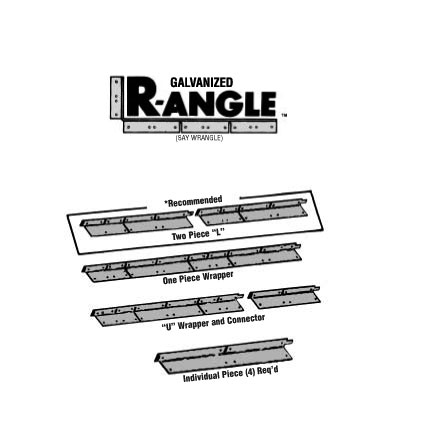

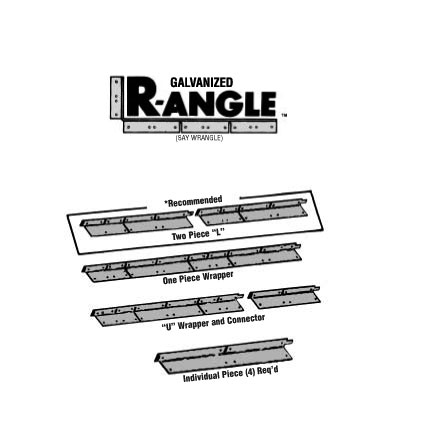

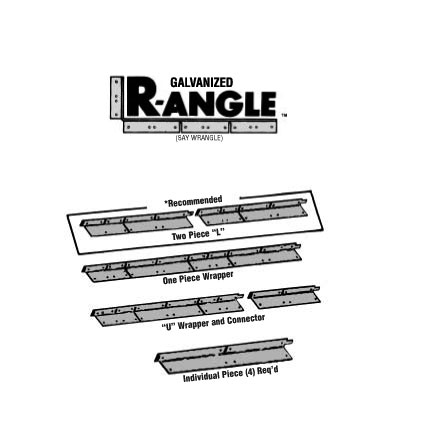

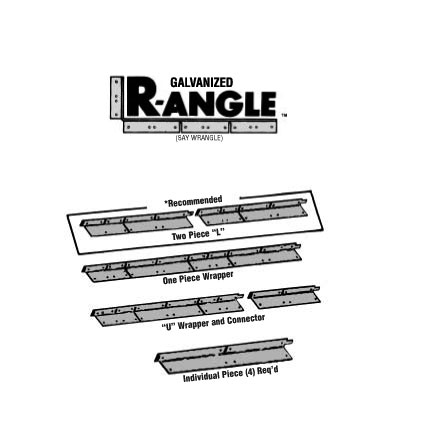

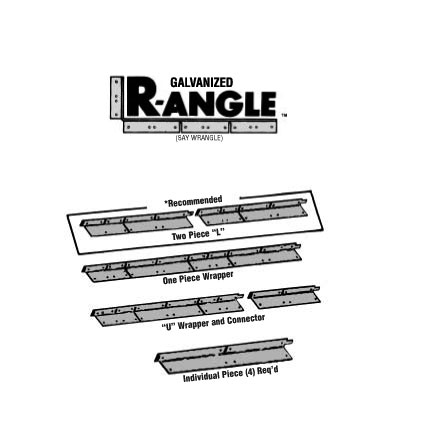

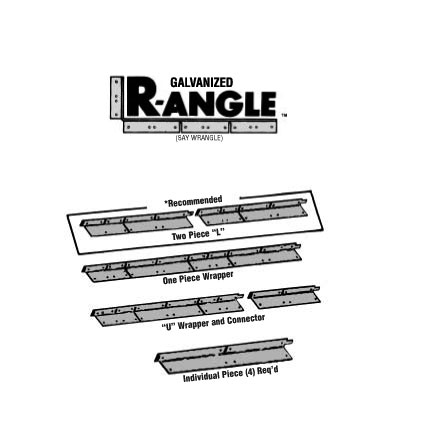

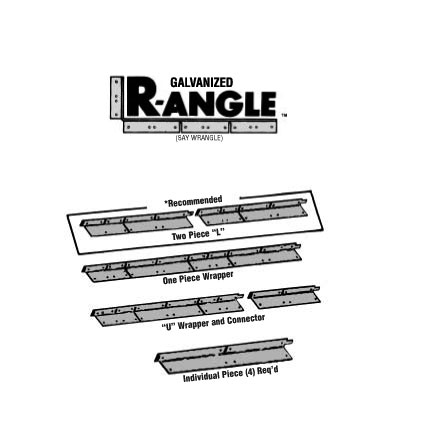

INST – E – 1.5″X1.5″X16GA

R-Angle reinforcement brackets 1.5″x1.5″ made from 16ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST – F – 1.5″X1.5″X14GA

R-Angle reinforcement brackets 1.5″x1.5″ made from 14ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST – H – 2″X1.5″X10GA

R-Angle reinforcement brackets 2″x1.5″ made from 10ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST – I – 2.25″X1.5″X10GA

R-Angle reinforcement brackets 2.25″x1.5″ made from 10ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST – J – 2.5″X1.5″X10GA

R-Angle reinforcement brackets 2.5″x1.5″ made from 10ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST – K – 2.875″X1.5″X10GA

R-Angle reinforcement brackets 2.875″x1.5″ made from 10ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST – L – DOUBLE 2.5″X1.5″X10GA

Double R-Angle reinforcement brackets 2.5″x1.5″ made from 10ga galvanized G-60 material. Shipped installed back to back from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

INST- G – 1.5″X1.5″X10GA

R-Angle reinforcement brackets 1.5″x1.5″ made from 10ga galvanized G-60 material. Shipped installed from the factory on your duct or fittings. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

J-35 Frame

FOR SMC USE ONLY (used for calculation when customers take off J-35 frames) NOT TO BE SELECTED FOR CUSTOMER ORDERS

KD – E – 1.5″X1.5″X16GA

R-Angle reinforcement brackets 1.5″x1.5″ made from 16ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – F – 1.5″X1.5″X14GA

R-Angle reinforcement brackets 1.5″x1.5″ made from 14ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – G – 1.5″X1.5″X10GA

R-Angle reinforcement brackets 1.5″x1.5″ made from 10ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – H – 2″X1.5″X10GA

R-Angle reinforcement brackets 2″x1.5″ made from 10ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – I – 2.25″X1.5″X10GA

R-Angle reinforcement brackets 2.25″x1.5″ made from 10ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – J – 2.5″X1.5″X10GA

R-Angle reinforcement brackets 2.5″x1.5″ made from 10ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – K – 2.875″X1.5″X10GA

R-Angle reinforcement brackets 2.875″x1.5″ made from 10ga galvanized G-60 material. Shipped loose to be installed in the field. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

KD – L – DOUBLE 2.5″X1.5″X10GA

Double R-Angle reinforcement brackets 2.5″x1.5″ made from 10ga galvanized G-60 material. Shipped loose to be installed in the field mounted back to back. R-angle adds rigidity to your ductwork to minimize deflection and allow your duct to be constructed from a lighter gauge.

Large End

Large end or female end is a plain end treatment for round fittings with no crimp made to actual size. Spiral end and complete seal will slip inside of large end.

Large Pittsburgh

Large Pittsburgh seams use a male flange and a female pocket of 5/8″ with tab that after the male end is inserted is pounded over the top to ensure a secure longitudinal seam. Pittsburgh seams are approved for +/-10″ of pressure.

Neoprene Gasket

Neoprene gasket uses a solventless high tack rubber based adhesive to allow for peel and stick applications. Gasket is closed cell to provide a superior, virtually air tight seal.

SPECSRaw – Butt Weld

To be used only with welded pressure files. Duct or fitting is fabricated with raw ends, no end treatment applied, no notches or flanges. This allows for a flush weld in the field to the next piece.

Raw for 4 Bolt

Duct or fitting is fabricated with raw ends, no end treatment applied, no notches or flanges.

Raw for Slips

Duct or fitting is fabricated with raw ends notched at the corners to allow for connection with the use of slips only.

Slip & Drive

Standard slip and drive construction, slips will default to the width of the part entered and drives will default on the height.

Small Pittsburgh

Small Pittsburgh seams use a male flange and a female pocket of 1/4″ with tab that after the male end is inserted is pounded over the top to ensure a secure longitudinal seam. Pittsburgh seams are approved for +/-10″ of pressure.

Snaplock

Snaplock seams use a male side with a button punch at 2″ intervals and a female side with a hemmed pocket that when joined create a solid and reliable longitudinal seam on ductwork and fittings up to +-4″ of pressure. Screws required at both ends of duct at 4″ pressure, as well as on 3″ pressure when width is larger than 48″.

Spiral End

Spiral end fittings are also known as male ends slip inside of spiral pipe. Fittings are inserted to the stop bead and fastened with screws or rivets. Spiral ends can be with or without crimp

Standing Slip & Drive

Standard slip and drive construction when one side exceeds 20″, slips will default to the width of the part entered and drives will default on the height.

TDC Assembled

TDC fittings fully assembled, all corners installed. Additional accessories such as cleats, nuts & bolts, gasket shipped loose (ONLY FOR USE WITH FITTINGS, NOT COIL LENGTH DUCT).

TDC Duct Assembled

TDC coil line duct fully assembled, all corners installed. Additional accessories such as cleats, nuts & bolts, gasket shipped loose

TDC L’s w/Corners

TDC designation for straight duct in L shaped sections. Corners will be installed in each L section resulting in 4 corners factory installed. All other corners and accessories are shipped loose.

TDC Loose Corners

TDC fitting usually shipped knocked down. All accessories shipped loose.

Tig Weld

Tig welding uses heat generated by an electric arc struck between a consumable tungsten electrode and the piece to fuse metal in the joint area and produce a molten weld pool joining without filler.

Wire Feed Weld

Wire feed welding joins metal by heating the piece and a continusously fed filler metal electrode with an electric arc. The filler metal serves as both heat source and filler metal for the welding point.