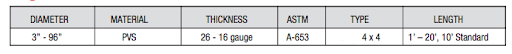

Polyvinyl Duct (PVS)

Polyvinyl Duct (PVS)

Polyvinyl Duct (PVS)

4x1 PVC for Underground Duct Systems

Sheet Metal Connectors, Inc. (SMC) PVC Underground Pipe and Fittings with E-Z Flange and Barrel Clamp or Standard Slip Connection.Single-Wall PVC Spiral Pipe

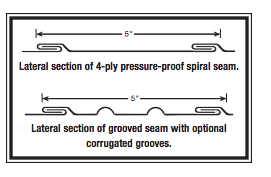

Sheet Metal Connectors, Inc. PVC spiral pipe is formed from a coil of metal into a rigid PVC tube with a 4-ply spiral lockseam. It has a smooth interior for low friction loss with the grooved seam entirely on the outside. This pipe for underground duct systems has a resistance to crushing approximately 2 1/2 times that of longitudinal lockseam. Optional corrugations are available which increase the rigidity of the pipe by approximately 300%. Pipe sections can be joined together by an E-Z Flange with Barrel Clamp, E-Z Flange Jr. with Barrel Clamp, or Standard Spiral Pipe Connector.Single-Wall PVC Spiral Pipe

General

The use of PVC duct pipe eliminates the need for encasing in concrete. Because no additional concrete is required, savings can be considerable. By combining the strength of steel and the chemical inertness of plastic, PVC ductwork is lightweight as well as corrosion and weather resistant. PVC ductwork will not rust, chip, crack, peel, corrode or produce odors. Although light in weight, PVC ductwork is strong enough to walk on and will not collapse under concrete. PVC duct pipe is specified by more engineers and architects than any other underground PVC pipe air conditioning duct.Durability

PVC ductwork is a rugged, durable material that will take ordinary shipping and handling without damage. PVC underground ductwork needs no protection in earth from sand, concrete or plaster. It is not affected by the minerals and salts found in normal backfilling materials. PVC ductwork has also passed thousands of accelerated salt spray and humidity cabinet tests with no loss of adhesion or corrosion resistance. It can be cut and formed with regular sheet metal equipment and tools with no harm to the coating. Even the largest diameter ducts are easily cut with portable metal-cutting saber saws or circular saws.Connections

E-Z Flange Jr. with Barrel Clamp - 6” to 24” Diameter

The E-Z flange jr. is a 5/8” flange turned out 90° on each end of the spiral pipe and fittings. The installer applies a gasket on one flange, mates the two flanges together, and attaches the barrel clamp. For field cuts a 5/8” flanged sleeve is available, cut the PVC spiral duct to the measured length and apply the sleeve. *For dimensional data please refer to the E-Z Flange Specification ManualE-Z Flange with Barrel Clamp - 26” to 96” Diameter

The E-Z flange with barrel clamp can be factory installed or shipped loose for field installation. A set consists of two E-Z flanges and one barrel clamp. For field installation, the installer attaches the E-Z flange to the PVC pipe or duct fittings with screws or pop rivets. Next, the installer applies the gasket to one flange, mates the two flanges together and attaches the barrel clamp. SMC also installs E-Z flanges. Flanges are fastened and internally sealed on all ends of the spiral pipe and fittings. *For dimensional data please refer to the E-Z Flange Specification ManualStandard Spiral Pipe Connector

Pipe to Pipe connections are made by using a fitting size coupling that slips inside the mating pipe sections, as shown. A stop bead runs around the middle of the coupling to center the coupling in the connection. Secure the connection by installing sheet metal screws through the outer shell of the duct, 1/2 inch from the stop bead.PVC Duct Fittings

PVC Underground Duct Fittings

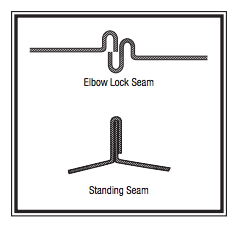

Sheet Metal Connectors, Inc. PVC duct fittings and connections are fabricated in 4 x 4 material to protect against corrosion from soil. SMC PVC duct fittings are manufactured with an elbow lock seam or standing seam. SMC fabricates PVC fittings in most sizes and configurations using our state of the art equipment. All joints and connections should be sealed in accordance with SMC’s recommendations to assure an air tight system. *The PVC fitting dimensional data listed in the PVC Specification Manual is for slip fit type connections only. For E-Z Flange PVC fitting dimensional data refer to the E-Z Flange Specification Manual.All PVC fittings can be manufactured with:

• E-Z Flange with Barrel Clamp - 26” to 96” Diameter • E-Z Flange Jr. with Barrel Clamp - 6” to 24” Diameter • Standard Spiral Slip Connector

Sealing

Spiral pipe and fitting slip connector joints must be sealed to prevent air leakage and to keep dirt and sand out of the duct system. PVC Tape is recommended as it is ideal for this usage. It has superior adhesive qualities, even in extremely hot or extremely cold weather. Also as an insurance factor, PVC Duct Sealer is available. This is a flexible and self-curing air pressure sealant. This can be applied from one-gallon cans by brush application. It provides a positive sealing of joints and screw holes. PVC Duct Sealer may also be obtained in a cartridge package. Approximate coverage is 375 linear feet per gallon at a 1/4” bead. *PVC tape is not required for the PVC E-Z Flange Spiral Pipe System.

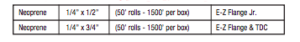

Closed Cell Neoprene Gasket

PVC Installation Guide - Underground Ducts

Install Above Water Table

The PVC underground duct system is not designed to be waterproof. Installation must be made safely above the water table. Ducts should not be placed where water infiltration may occur.Depth

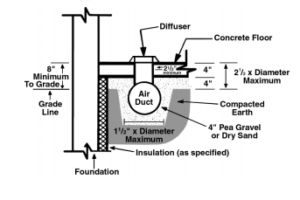

The top of the duct can extend into the cement, leaving a minimum of 2 1/2” of cement above the top, or the duct can be placed well below the cement. However, the duct should not be placed so deep that the weight on it will exceed the load capacities. The depth should not be more than 2 1/2 times the diameter of the duct.Trenching and Backfill

After the excavation has been completed, no special bedding is needed for the PVC Duct. It can rest right on the ground, and can be set in sand or light aggregate. Trenches should be pitched to prevent water buildup around the ductwork. Pea gravel or sand (or the material taken from the trench, if equivalent) can be used to backfill. Spread the backfill material evenly around the duct making sure there are no gaps, and tamping in place is a recommended practice. No cement is needed to fill in around the duct since the tamped fill holds the duct in place and the PVC coating prevents ground corrosion of the galvanized steel. This PVC coating is resistant to any minerals or salts that may be in the backfill soil.Large Diameter Ducts

Use E-Z Flange with Barrel Clamp for strength, rigidity and a virtual airtight system. Special care should be taken with large diameter ducts. Backfilling and tamping should be done without damage to the ducts. Temporary bracing can be used inside the ducts. Consult an engineer for the reinforcement schedule on large diameter ducts.Load Specifications

#1 Standard 4”-8” 400 lbs./Linear Ft. 10”-12” 600 lbs./Linear Ft. #2 Corrugated 14”-36” 1800 lbs./Linear Ft.*

*All ducts 14” or more in diameter are corrugated for extra strength. Where deeper burial or heavier loading is required duct gauges can be increased. Also angle rings and/or special bracing can be used.

Typical Underslab Duct

CAUTION: When backfilling or grading, care should be taken not to dump or push heavy loads directly on the duct, nor should heavy equipment be allowed to run over the duct. It can be crushed under thoughtless abuse.

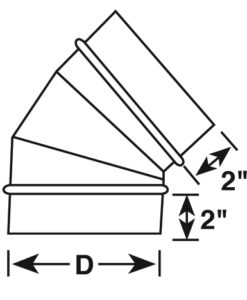

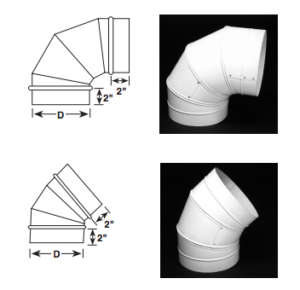

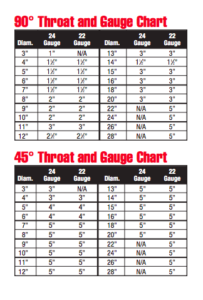

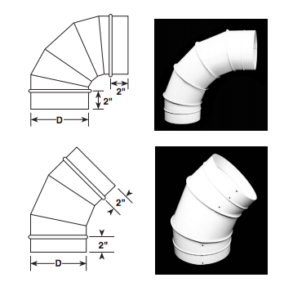

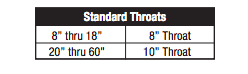

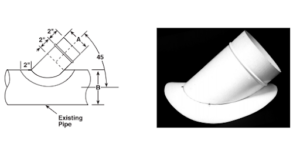

Adjustable Elbows & Angles

The throat radiuses are SMC’s standard for low pressure systems. Full sweep (C.L. Radius = 1.5 x D) are available up to 16” diameter.

Standing Seam Elbows

Standing Seam Elbows and Angles

Standing Seam fittings work well for medium pressure applications and offer an alternative to riveted elbows and angles. These are available from 8” through 60” diameters and fabricated as heavy as 16 gauge. Other diameters and throat radiuses are available.

Full Sweep Standing Seam Elbows

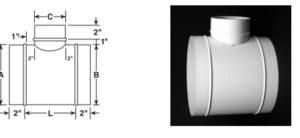

8”-30” will be a 5 gore standard throat construction. 32” and larger in diameter (1.5 x CL) 90 degree full sweep elbows are fabricated using two 45 degree angles connected with an E-Z flange and barrel clamp.90° Tee

Dimensions to be listed as follows: A, B, C L = “C” + 4”

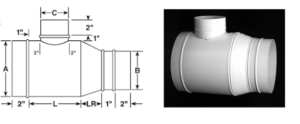

Tee with Reducer

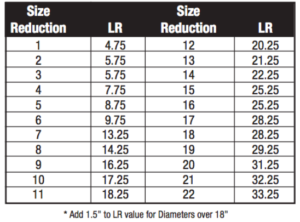

Dimensions to be listed as follows: A, B, C L = “C” + 4” L.R.: See Chart

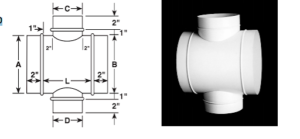

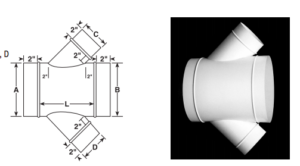

Cross

Dimensions to be listed as follows: A, B, C, D L = Largest of “C” or “D” + 4”

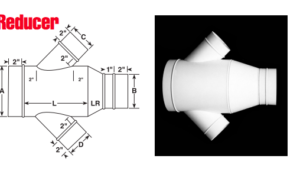

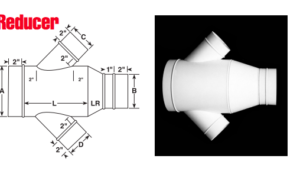

Cross with Reducer

Dimensions to be listed as follows: A, B, C, D L = Largest of “C” or “D” + 4” L.R.:

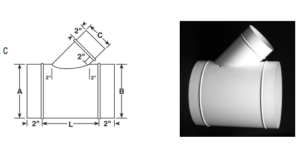

Lateral

Dimensions to be listed as follows: A, B, C L = (1.414 x C) + 4”

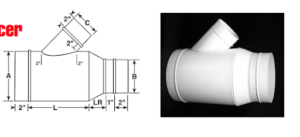

Lateral with Reducer

Dimensions to be listed as follows: A, B, C L = (1.414 x C) + 4” L.R.: See Chart

Lateral Cross

Dimensions to be listed as follows: A, B, C, D L = 1.414 x (Larger of “C” or “D”) + 4”

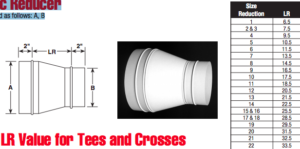

Lateral Cross with Reducer

Dimensions to be listed as follows: A, B, C, D L = 1.414 x (Larger of “C” or “D”) + 4” L.R.: Refer to page 7

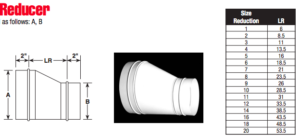

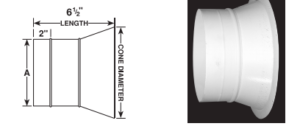

Eccentric Reducer

Dimensions to be listed as follows: A, B LR = (See Chart)

Concentric Reducer

Dimensions to be listed as follows: A, B LR = (See Chart)

LR Value for Tees and Crosses

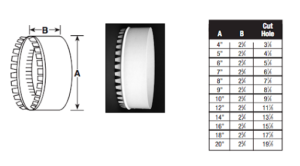

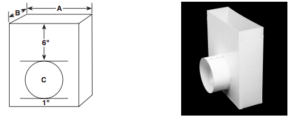

E-Z Tap Collar

Order as follows: A equals diameter

E-Z Tap Collar with Damper

Order as follows: A equals diameter

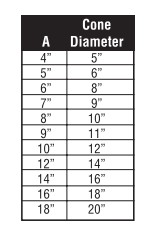

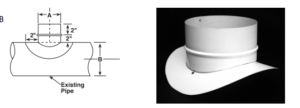

E-Z Tap Conical Takeoff Collar

Order as follows: A equals diameter

E-Z Tap Conical Takeoff Collar with Damper

Order as follows: A equals diameter Dampers available in stainless steel with matching hardware

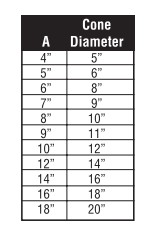

90° Swedged Saddle

Dimensions to be listed as follows: A on B

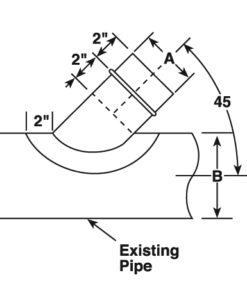

45° Swedged Saddle

Dimensions to be listed as follows: A on B

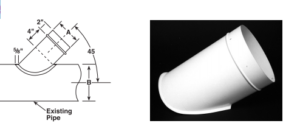

90° Full Saddle

Dimensions to be listed as follows: A on B

45° Full Saddle

Dimensions to be listed as follows: A on B

Notched Collars

Order as follows: A equals diameter

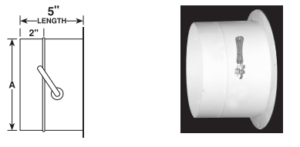

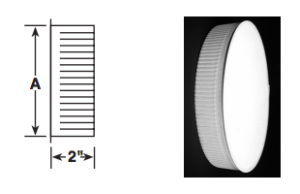

End Cap (Plug)

Dimensions to be listed as follows: A, equal diameter

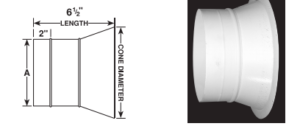

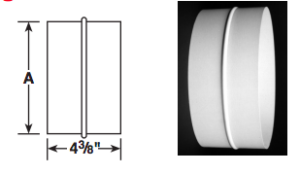

Connector (Coupling)

Dimensions to be listed a follows: A, equals diameter

PVC Accessories

PVC Touch-Up A special formula of poly-vinyl chloride for air drying for quick scratch repair. Spray Can (6per case)PVC Tape

Normally all that is needed to complete an installation are sheet metal screws and PVC Tape. Tape is strong, permanent; ideal for use underground. Has superior adhesive quality even in hot or cold weather. 2” x 108 ft. (24 rolls per case)90º Register Saddle

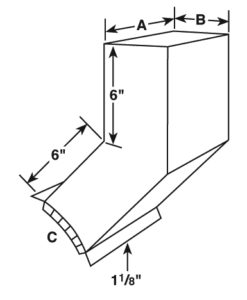

Dimensions to be listed as follows: A, B, C

45º Register Saddle

Dimensions to be listed as follows: A, B, C

Register Boot

Dimensions to be listed a follows: A, B, C

PVC Fume Exhaust Duct Systems

PVC is an ideal material for many fume exhaust applications. Combining the strength of steel with the chemical inertness of polyvinyl coated duct offers completely integrated systems with diameters from 4” to 86” spiral pipe and all standard and special fittings that may be required. The assembly of the system is completed by the use of PVC duct sealer and PVC tape.Learn about PVC lab tests that were conducted, which provide a guideline for polyvinyl coated ducting of exhaust fumes.

One Type Available

PVC for fume exhaust duct systems is available in 4x4 coated. 4x4 has a 4 mill coating of polyvinyl chloride on both sides. It gives maximum interior and exterior protection.Flat Sheets Available

Also available in gauges from 26 ga. to 16 ga. are flat sheets for making hoods or forming rectangular duct systems.Limitations

The practical temperature range is -30° F to 200° F.PVC duct has been used successfully in many exhaust systems, including in many laboratory settings, although it is not suitable for all applications. Type 304 or 316 stainless steel can be used as an alternative material in more corrosive applications, but it is up to the user to determine the suitability of the material used. Samples of materials used in Sheet Metal Connectors, Inc. products can be provided upon request to determine their corrosion resistance characteristics.

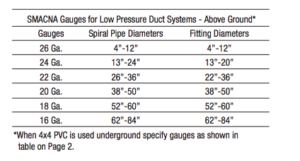

Specifications for PVC Fume Exhaust Duct Systems

Fume exhaust system shall be PVC type 4x4 as manufactured by Sheet Metal Connectors, Inc., Minneapolis, Minnesota. Gauges shall be standard SMACNA gauges for low pressure systems.Round ducts shall be roll-formed spiral pipes. Fittings shall be factory fabricated with stainless steel rivets. All fitting seams shall be caulked on the inside with PVC duct sealer.

All connecting joints are slip-fit. Apply PVC sealer to all raw edges and male ends. Secure joint connection by installing sheet metal screws with a minimum spacing around 6”. Apply PVC sealer over screws and seam of joint and wrap with PVC tape. Repair any damage to the coating with PVC touch-up paint.